Through developing a graphene-nanosheet-based ink, collaborators at the University of California – San Diego and the National Taiwan University of Science and Technology have produced flexible, wearable, ultrathin sensors. Fabricated by printing multiple layers directly onto medical tape, the printed graphene sensors can be easily affixed to skin. Due to their high strain sensitivity, deformations to the sensor caused by subject movement can allow non-invasive health monitoring. Further, through combining multiple small sensor patches to make different geometries, the sensors accurately follow hand motions and can even monitor eye-blinking and pulse.

The development of wearable sensors utilizing nanostructured materials has been key to progress in achieving accurate physiological measurements. The main reason being that nanomaterial-based sensors exhibit greater flexibility and dexterity akin to the skin, unlike the more rigid electronics-based alternatives.

The sensor developed by Long Wang at the University of California and colleagues detects strains and deformations from the resulting measurable change in the resistance across it, which corresponds to the “amount” of deformation. Previous work had explored the strains involved when bending a finger covered in these sensors. Now by printing the sensors directly onto medical tape the researchers have shown how the sensors can monitor other parts of the body.

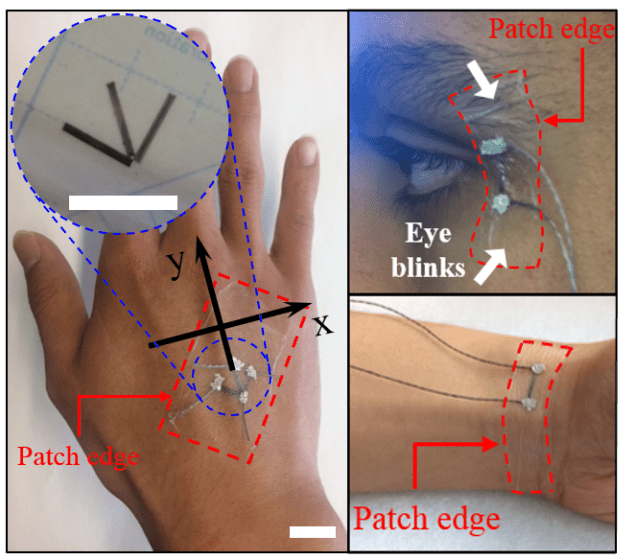

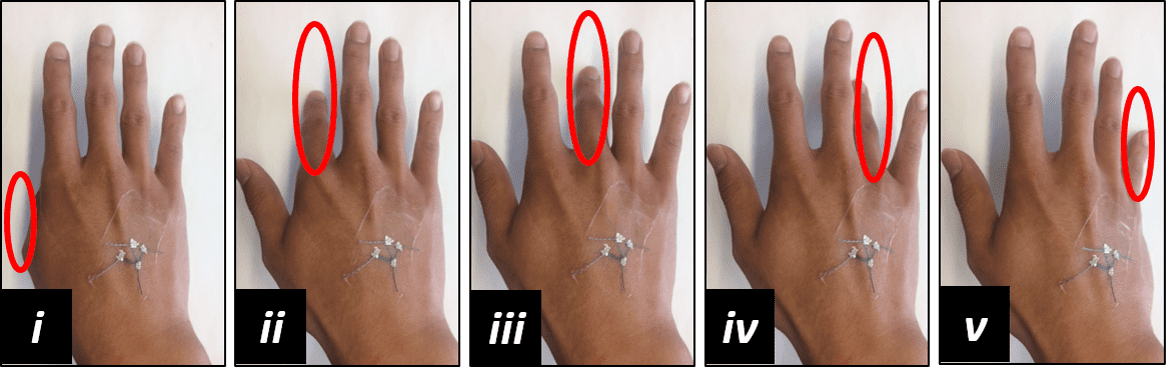

One example is the use of a rosette-shaped arrangement of several rectangular 12×1 mm multi-layer sensors to measure the change in strain distribution across the hand when using different muscle groups. Because the combination of different strain measurements across the group of sensors within the rosette is unique to each finger, the sensors can identify different finger motions.

The distinction between muscle groups is possible due to the high sensitivity of these devices, where sensitivity is defined as the normalized change in resistance compared with the corresponding change in applied strain. The printed graphene sensors also exhibit reproducible, reversible trends in their sensing ability for up to 1000 strain cycles, making them extremely durable.

How the sensors are made

Graphene nanosheet ink is key for the production of this multilayered sensor, as it makes patterning directly onto the medical tape possible. The researchers prepared nanosheets by following a highly efficient, low-cost and environmentally friendly water-assisted liquid-phase exfoliation procedure. They mixed graphite in a co-solvent solution and then sonicated for several hours at a fixed temperature and then centrifuged samples to separate out any undesired solids. They then mixed this graphene nanosheet solution to obtain a printable ink, which they printed directly onto the medical tape in 2D patterns with a resolution of 60 μm using a micropatterning instrument called SonoPlot.

What they can do

These sensors have also successfully demonstrated their capacity to monitor eye blinking; where the change in resistance arises due to sensor deformation as the eye closes. By monitoring deformations in the skin the researchers were able to measure the heart rate accurately enough to distinguish the increase during exercise compared with the resting baseline pulse.

Integrating this ultrathin and conformable sensing technology with medical tape presents a neat solution for the attachment of sensors to the skin. This research avenue is set to have a significant impact on human monitoring due to the versatility the approach offers for using these graphene-based sensors anywhere on the body. More information on this paper can be found in Nanotechnology.